When the paper leaves the dryer section its solid content has increased to about 90-95. It has a major impact on the structure and runnability of the paper and thus the operating efficiency of the machine Wahlstrom 1969.

Paper Machine Draw Calculation Manufacture And Paper Machine Draw Calculation Supplier In China

To control the vacuum pressure distributor in the machine designer used Siemens SMT version 331Solidworks 2016 was used to draw machine components and cam calculations.

. It determines the dryness of the sheet entering the dryer section. Important deep drawing process parameters are calculated by using standard formulas as follows Blank Diameter D d2 4dh05 -------1 Draw Ratio hd p -------2 Table I The relationship between Hd ratio number of draws If hd p 075 Then no. This results in a high.

The machine to be designed is shown in table 1. 217 Paper Machine Calculations The relationships between basis weight consistency paper machine width and speed and production rates are easily derived. Then enter the new basisgrammage weight.

Water from the paper by sucking it out of suspension. If use 250gsm paper one 9oz cup cost. To design a machine which will produce less noise and vibrations.

Water Consumption Paper Machine Uptime Uptime Annual Hours Sheet On Reel X 100 Annual Available Hours Excludes Scheduled Outages 24 Hours Other Mill Services Affect No Factor For Machine Speed Highest Observed 97 on Liner Machine Lowest Observed 58 on Coated Machine Paper Machine Uptime Guidelines TIP 0404-47. Previous work on the drive power for paper machine dryers covered a 15 meter diameter cylinder. Of draws 2 If 15 hd p.

3 From the finished deckle wire width can be calculated Ref page 110. This is dried in the machine to produce a strong paper web. The purpose of this article is to highlight some of the effects as they were recorded on.

Aside from making the machine more susceptible to web breaks and inevitable lower efficiencies increased draws also affect final web properties. Buy Paper from paper suppliers for this 9oz cups sheet paper size 85664mm x 557mm rolling paper width 685mm. Drive Power and Torque in Paper Machine Dryers.

They have many models with built in algorithms for tension control and winding built up calculations. Next enter the original basisgrammage weight and total weight. The latest newsprint paper machine has line data of 1700mmin speed paper width 9000mm and the total drive capacity of about 20000kW.

Recent paper machines utilize AC drive technology. 0-9694628-2-4 This new book offers an update on current paper machine developments and operating practices and compares design approaches by major paper equipment manufactur ers. To construct a machine which will shred 20 sheets.

Multi-layer paper machines and paper board machines include additional forming sections one forming section for each layer of paper. For a quick reference guide on the basis weight impact on percentage paper yield try this chart. The paper web passes over rotating heated cast iron cylinders and the most of the remaining water is removed by evaporation.

It is assumed that the speed of the stock exiting the headbox is approximately equal to the speed of the machine wire. Tension and Draw Control on Paper Machine 10142010 647 AM please check eurotherm now parker drives. However there is often a need for some simple estimates of dryer sections of paper machines.

The flow from the Headbox is directed in positive machine direction and the cross direction is in the perpendicular plane against MD. Of draws 1 If 075 hd p 15 Then no. In the case of a large sectional paper machine drive system.

The third part of the paper machine is called the drying or dryer section. In this thesis the tissue machine was defined with three directions machine direction MD cross direction CD and thickness ZD. Great ideas are started on paper the world is educated on paper businesses are founded.

The following parameters is important in the final tissue paper. Pressing operation is important for the capacity and economy of a paper machine and has great influence on paper quality. 40 40 means 1 cm of belt take 40 kg load V Belt speed d1 x n1 V ----- msec 19100 d1 pulley dia n1 Motor rpm.

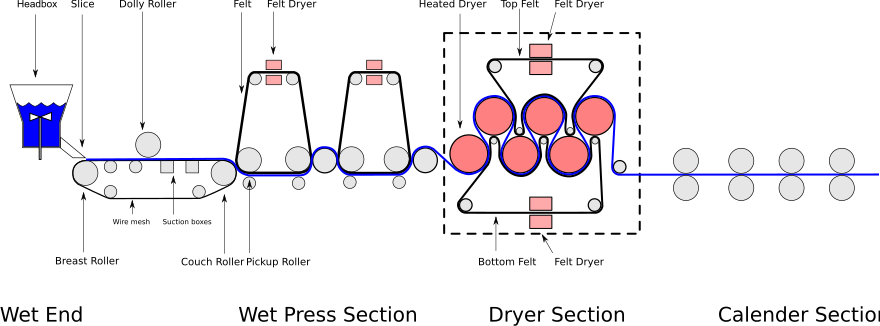

Modern paper-making machines are based on the principles of the Fourdrinier Machine which uses a moving woven mesh to create a continuous paper web by filtering out the fibres held in a paper stock and producing a continuously moving wet mat of fibre. Forming section drives have a high friction load due to the suction normal forces of the water through the wire mesh. 1000USD 140 000 000714 USD.

Cylinder machines and Fourdrinier machines. Water removal in the press section of paper board and pulp machines has an important influence on machine efficiency and cost. Traditionally paper machines have been divided into two main types.

55 depending on the paper grade and press se ction design. Basic parameter in the design of a paper machine dryer drive system whether it has an open gear enclosed gear or felt drive is the drive power requirement. For larger paper machines each motor capacity exceeds 1000kW so large capacity single drive inverters are being applied.

The paper weight basis weight may vary from light tissue about 10 grams per square metre 003 ounce per square foot to boards of more than 500 grams per square metre 16 ounces per square foot. If you want to buy one ton 200gsm paper for the sheet paper should be 1000 x 477 567 841 KG For bottom 1000 x 09 567 159 KG. Paper Cup Machine Specifications Specification Rating.

Paper Machine Design and Operation--Descriptions and Explanations By Gunnar Gavelin 1998 222 pp Published by Angus Wilde Item Number. The TAPPI drying rates shown in Figure 14 are one source. 2 The Paper Machine 21 The paper machine The main challenge facing any paper machine Figure 1 is to distribute the raw material evenly to produce a homogeneous product.

First select the unit of measurement. Design paper slitting rewinding machine developing country 1. The paper at random until the particles are small enough to pass through a mesh.

The method used is to prepare the raw material in several steps before diluting it. 57 BELT WIDTH IN FLAT PULLEY P x C2 x C3 x 1000 bo ----- FUN x V Where bo Belt width P Kilowatt of motor C2 Over load factor 50 of normal load of motor For paper Industry C2 12 constant factor C3 Ratio between both pulley FUN Belt type ie. But you will have to have a plc connecting all the drives in a network which will pass on the parameters to the drives after doing all.

To formulate a study on different elements of the shredder machine like the blades frame transmission system etc. Paper machine dryers have been modelled using computers and rigorous application of heat and mass transfer principles. Introduction Paper is a renewable and recyclable plant-based product that connects us in so many ways to the important things in life PAPERbecause 2015.

2 Speed of Paper Machine On the basis of information and data paper machine speed can be calculatedRef page 106. The first open draw experienced in a paper machine is off the first smooth surfaced center roll. In this case data compiled from industry averages are frequently used.

A press section design equation based on the decreasing.

Schematic Of A Paper Machine Download Scientific Diagram

Machine Wire An Overview Sciencedirect Topics

Paper Machine Draw Calculation Manufacture And Paper Machine Draw Calculation Supplier In China

0 comments

Post a Comment