Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoe-type bearings. The present mill inlet chute can be used for the two compartment ball mills only in which primary and finish grinding both are takes place.

Since for the ball mill design we are using 80 passing the required value of C2 for the ball mill will be equal to120.

. Design Method of Ball Mill by Discrete Element Method collected. C3 is the correction factor for mill diameter and is given as. Ball Mill Design Handbook Operational Manual Raymond Grinding Mill Service Support.

Ball Mill Simulation The simulation model for tumbling ball mills proposed by austin klimpel and luckie akl was used to simulate wet grinding in ball mills and it gave good agreement with experimental results from a 082 m diameter by 15 m ball mill Online Chat Ball Mill Theory And Free DownloadFeb 16 2013 ball mill of slag. The mill lining and free design More detailed. Group number 3.

The residence time in ball mills is long enough that all particles get. The best calcite ball mill maintenance pdf. Bond Ball Mill Ball Mill Instruction Manual PDF Ball Mill Diagram.

Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the dis-. Swachh bharat abhiyan ka essay short essay on my heritage day. Find 7 2nd HandUsed RAYMOND MILLS in.

With Lloyds ball milling book having sold over 2000 copies there are probably over 1000 home built ball mills operating in just America alone. PSP Engineering has continuously refi ned the design of its ball mills. Potential threats before they become a problem such as.

Jaw crusher Hammer crusher Cone crusher Raymond mill Ball mill PDF. Based on his work this formula can be derived for ball diameter sizing and selection. 813 Power drawn by ball semi-autogenous and autogenous mills A simplified picture of the mill load is shown in Figure 83 Ad this can be used to establish the essential features of a model for mill power.

Substation maintenance manual pdf at manuals library 16 best manual lathe images in 2019 lathe manual lathe ball mill maintenance installation procedure mill operator resume samples qwikresume machine operator resume writing guide 12 templates 2020 safe. EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and The Built Environment. Ball Mill Submitted to.

Total filling ratio of grinding compartment. In recent days the Ball mill grinding systems are used with the Roller press and it is. The mill is used primarily to lift the load medium and charge.

Among hammer mills there are several styles to choose from. 𝐶𝐶3 244 𝐷𝐷 02 3 However it is important to note that C3 0914 vessel used in. Free Download Of Ball Mill Cement Plant Pdf.

Ball mill manual pdf maintenance podwierzbaeu. Feb 21 2015 Cytec Handbook. However for each the functionality remains basically the same.

Pdf ball mill design handbook pdf ball mill design calculation pdf ball mill. Nominal 3029 th per mill. Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials cement lime and ceramic materials.

And back lash measurement. It may be a closed or open circuit grinding systems. If a product all finer than a certain critical size is required the capacity of the ball mill is increased considerably by using it in closed circuit with a classifier and this increase is made still greater by increasing the circulating load in between the ball mill and the classifier Fig.

The basic parameters used in ball mill design power calculations rod mill or any tumbling mill sizing are. The diameter of the gibbsite powder was measured using a Master Sizer 2000 Sysmex Corpora-tion. Shredders jaw crushers ram-fed grinders roll mills ball mills and more.

Details of the experimental conditions are given in Table 2. Circulating Load Calculation Formula. Ball mills are used the size reducing or milling of hard materials such as minerals glass advanced ceramics metal oxides solar cell and semiconductor materials nutraceuticals and pharmaceuticals materials down to 1 micron or less.

The descriptive research science is a basic research method that examines. Additional power is required to keep the mill rotating. Material to be ground characteristics Bond Work Index bulk density specific density desired mill tonnage capacity DTPH operating solids or pulp density feed size as F80 and maximum chunk size product size as P80 and maximum and finally the type of.

Example mistyhamel response from mastercam users can control. The inspection includes an examination - Hydraulic and lubrication problems of the overall condition of the separator - Cracks in ball mill internals including a check of wear on the rotor and. Liner design and material of construction.

Results and Discussion 1. This article borrows from Lloyds research which was obtained from the commercial ball milling industry and explains some of the key design criteria for making your own ball mill. Why have a large circulation load.

Five Key Styles Hammer mills are just one type of machinery among the larger category of size reduction equipment which also includes. One of three SAG mills with 975 m diameter and 2 x 4000 kW drive power. Used ball mill for sale ball mill design in india south africa PDF.

Like white men and women may carry a gear Gerber is Unstoppable. Total mill feed incl. Dm.

This relationship was successfully used for the scale-up of a rocking ball mill and the optimum design and operating conditions for the rocking ball mill could be estimated by the specific impact. Dk the P90 or fineness of the finished product in microns umwith this the finished product is. 85 dB A f Page 4 PartschW 09 Oct 2006 IDatenPartschWPOLYCOM MineralsAnlagenCERROMUETrainingPresentationA Ball Mill Design-Overviewppt.

This allows specialists to detect maintain overall mill performance. Click here to load reader. Autogenous mills semi-autogenous mills and ball mills for wet.

Highlow wave ball mill liner Materials The selection of the material of construction is a function of the application abrasivity of ore size of mill corrosion environment size of balls mill speed etc. Design 3379 th per mill. Service Life Of Raymond Mill RollerRaymond Mill Maintenance.

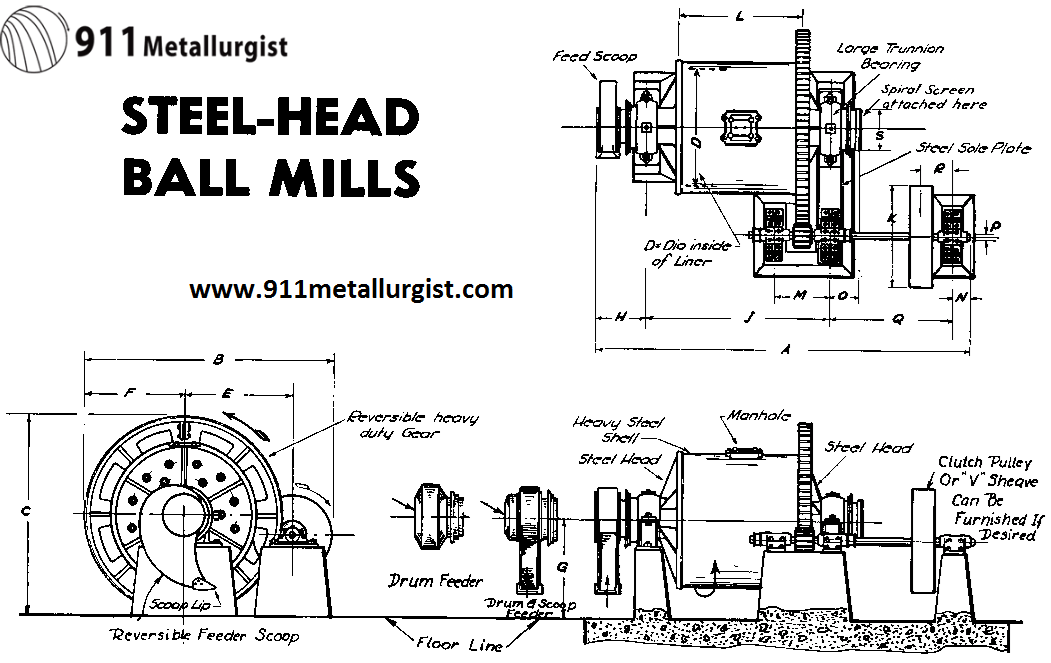

Ball Mill Application and Design. SAG and ball mill for gold ore grinding. Dr Ibrahim Ismail Dr Ahmed Sherif Prepared by.

The grinding rate of gibbsite in tumbling and rocking ball mills using fins was well correlated with the specific impact energy of the balls calculated from Discrete Element Method simulation.

Ball Mill Design Power Pdf Mill Grinding Iron Ore

Pdf Ball Mill Datasheet Mo Kh Academia Edu

Pdf Design And Fabrication Of Mini Ball Mill

Tubular Ball Mills Sciencedirect

Ball Mills An Overview Sciencedirect Topics

High Energy Ball Milling 1st Edition

Tubular Ball Mills Sciencedirect

Pdf Design And Analysis Of Ball Mill Inlet Chute For Roller Press Circuit In Cement Industry Editor Ijret Academia Edu

0 comments

Post a Comment